Comprehensive range of Seaport Passenger Boarding Bridges (SPBBs) & Gangways

Docking Cabin

The inside of the cabin is spacious and bright to improve the experience of the passengers and to facilitate the driving of the boarding bridge.

- Various possible designs, including specific designs to fit with new generation mega-cruise ships with external lifeboats

- Retractable telescopic docking ramp for optimal flexibility

- High precision sensors and fast response actuators that automatically follow the ship

- Safety auto-undocking designed to automatically disengage from the vessel in case of emergency

- Optimal all weather protection

Tunnels

The structure, made from high quality steel, has undergone a category C5-M paint process specifically for the marine environment, the same as that used on oil rigs.

- Tunnel dimensions and slopes designed to comply with national and international Accessibility Standards (EN, BS, ADA…)

- Multiple walkway configurations for different SPBB models and terminal needs.

- “Access for All” philosophy, including handrails, transition ramps and flat surfaces for the turning of wheelchairs.

- Wide selection of quality finishes, including ceiling tiles, floor coverings, lateral enclosures and glazing systems.

- Various HVAC systems and solutions, including ADELTE’s own developed roof top systems.

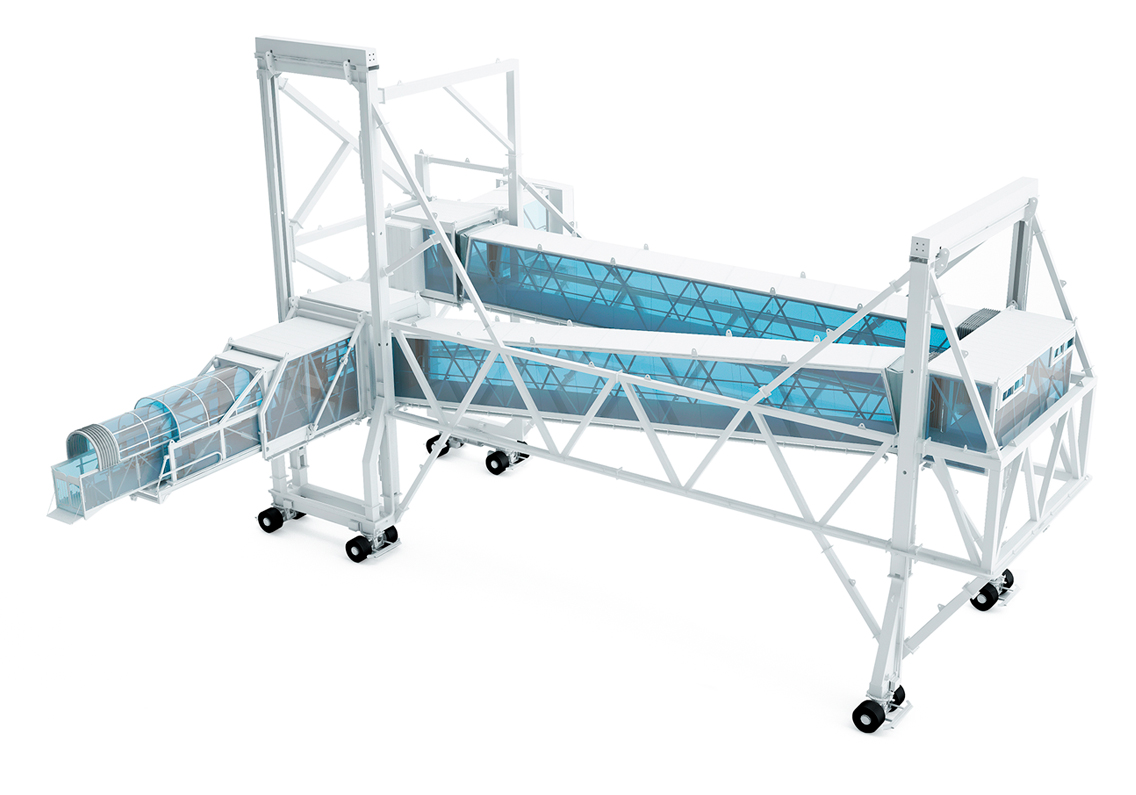

Structures

Structural compositions are optimized for a light and slender look in order to interference the least with the architecture of the building whilst ensuring durable and correct load distribution.

- Steel structures for maximum performance, durability and reliability

- 100% self-supportive on the quay

- Seismic, strong wind and fire-resistant design

- Paint protection designed to guarantee high durability in marine environments (duration of more than 15 years in a C5 atmosphere, according to ISO 12944)

- Aesthetic designs, visual integration, choice of colors

Elevation

Electromechanical or hydraulic systems are available as standard. Both are equipped with a redundant safety system that ensures the alignment of the lifting columns without the need for electrical detectors.

- Water proof aluminum slats for noise reduction for extended life

- Includes double safety brakes for automatically blocking the system in the event of power failure

- Synchronization of hydraulic systems is ensured by means of sensors, valves and control programming

- Redundant safety: a single column / cylinder is able to support the whole weight of the SPBB and raise the assembly at reduced speed

Translation

This consists of a solid simple or double wheel that is highly resistance to wear, independently controlled by a few variators through the PLC. The advanced design of the bogie allows instant access to any part of the traction system that requires maintenance.

- Bogie sets with rails or solid rubber wheels

- Includes anti-collision devices, safety brakes and sensor-based stop systems for maximum safety in translation

- Smooth acceleration and deceleration curves

- Guiding systems adapted to every port by means of different technologies (rails, sensors, GPS…)

Electrical and Control Systems

The control system allows all elements of the SPBB to be operated in a safe, secure and easy manner.

- The SPBB is designed to be operated by a single person

- The SPBB will perform the movements automatically once docked without the need of any personel on board.

- The PLC-based control system ensures that the status of every element of the SPBB is monitored and available at any moment

- Redundant electrical and mechanical systems limit and control all SPBB movements

- Touch-screen panel and remote controls, for a comfortable and safe operation

- Safety auto-undocking, designed to automatically disengage from the vessel in case of emergency

Seaport Passenger Boarding Bridge specifications

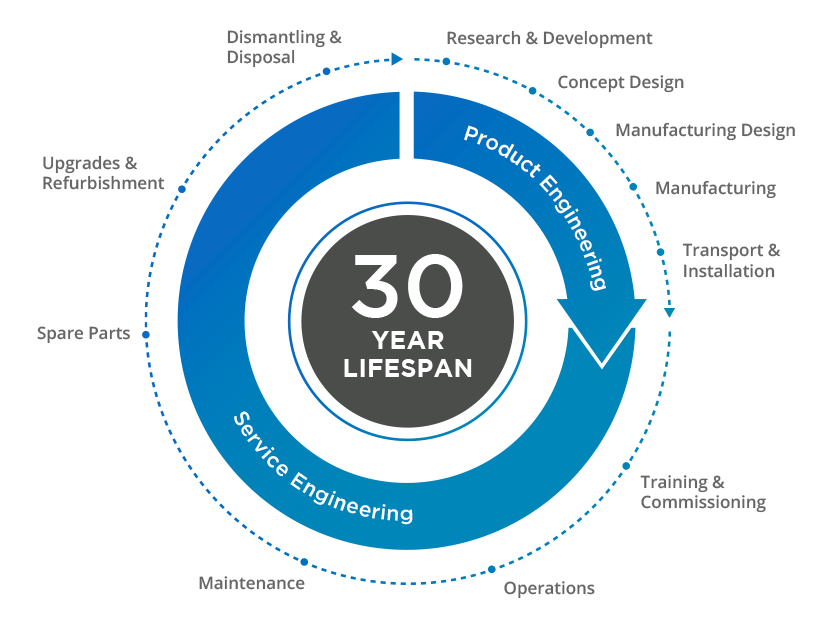

Each Ferry and Cruise Terminal is unique and deserves the solution that best fits its particular needs. Our Passenger Boarding Bridges are totally custom-designed by an experienced team of engineers and designers who take multiple variables into consideration: architectural requirements, berth layouts and load strengths, tidal ranges, vessel type, port operational logistics, climate conditions, etc. Tell us your needs and we will design the optimal PBB for you.

ADELTE’s elevation and translation technologies, associated with a sophisticated active-docking cabin, enable our Passenger Boarding Bridges to fit the different door positions of vessels and to dock a large variety of cruise and ferry vessels, including those with overhanging lifeboats.

Equipped with multiple sensors, PLC-based control system, safety auto-undocking procedure, redundant electrical and mechanical systems, and a seismic, strong wind and fire-resistant design, ADELTE’s Passenger Boarding Bridges provide total safety for people (passengers and operators) and structures (ships and terminal buildings) and comply with up-to-date worldwide safety and security standards.

We strongly believe that the moment a passenger enters one of our advanced boarding bridges they begin their journey. Therefore, design and successful technical conception are vital, with aspects like a comfortable tunnel gradient, handrails, non-skid flooring, significant thermal and acoustic insulation, hinged ramps with flat surfaces or wide tunnels for bi-directional passenger flows making a qualitative difference to a passenger’s perception of the service provided.

Quality is a must. All our Passenger Boarding Bridges are designed for an operational lifespan of 20 years. The structure is made of high quality steel and receives paint protection which ensures the highest durability in marine environments. All materials are tested and the manufacturing process is certified in order to guarantee outstanding reliability.

ADELTE’s unique design guarantees that wharf logistic operations around and under the PBB can be realized in optimum conditions without any structure interference.