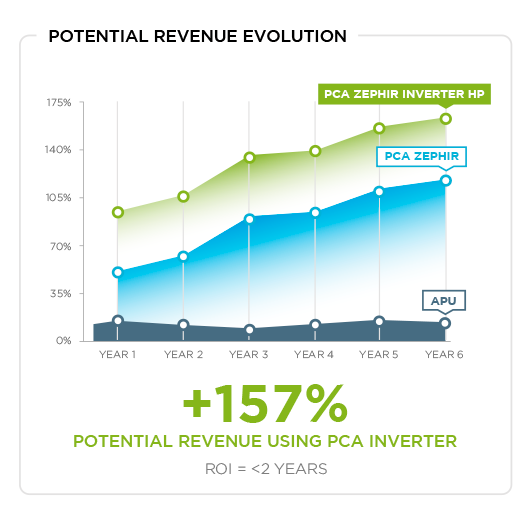

The above calculations are for illustration purpose only. ROI has been calculated under the online PCA simulator conditions that are described in the webpage.

The APU burn rates used are 100 kg/h for a NB and 250 kg/h for a WB. The Jet Fuel A1 cost is based on latest available data provided by IATA.

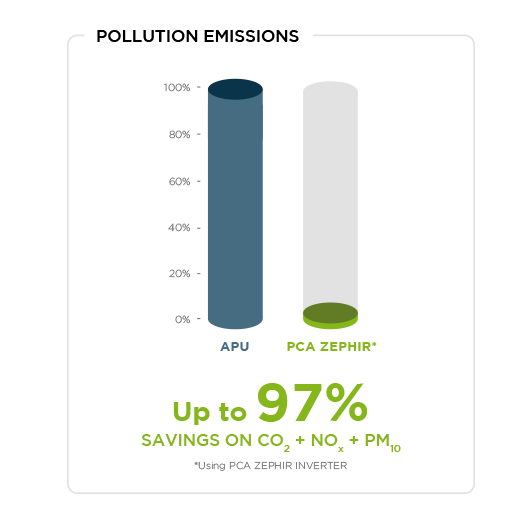

Emissions are calculated per ICAO Document 9889 Airport Air Quality Manual. The maximal admissible annual values of NOx and PM10 are 40µg/m³ per EU Directive 2008/50/EC.

The CO2 generated by the off-site production of electricity is 500 g / kWh average high value per EPTA (European Parliament Technology Assessment).

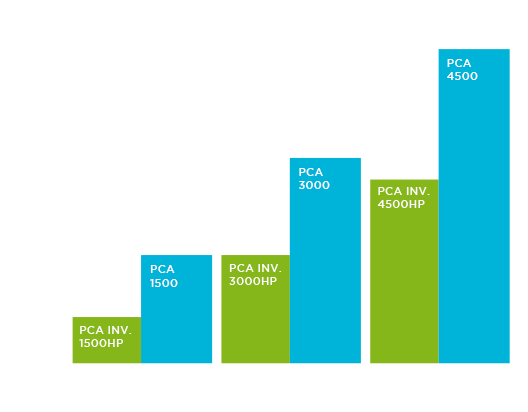

The PCA ZEPHIR Inverter HP incorporates the system Heat Pump for the supply of heating to the Aircraft. The heat pump system uses the refrigeration circuit of the equipment itself to generate heat, avoiding the use of electrical resistances in a temperature range up to -6ºC outside, depending on conditions.

With this system we are able to supply all the required heat capacity with a reduction in energy of up to 60% thanks to the efficiency of the refrigeration system with COP of 2.5.

The electric power consumed has been calculated under PCA unit nominal heating conditions for each aircraft body type and under ambient conditions of 0ºC / 90% Hr.

Only heat generation elements consumption has been indicated in the graphic: electrical heaters vs. frigorific heat pump.

Zephir Series are designed and engineered to deliver optimum airflow to each aircraft, using four compressors four phases and high efficiency direct drive centrifugal blower (VFD), while consuming the minimum energy.

ADELTE’s PCA Inverter is designed for cooling and heating stationed aircrafts. In heating mode, no electrical resistor is needed as a Heat Pump is integrated to the system which results in a much lower electrical power consumption.

Zephir units use R-410A refrigerant which respects the environment and the future generation to come. Its high efficiency significantly reduces refrigerant load and CO2 emissions

Zephir PCAs are point-of-use units which can fit any layout platform and can be installed on any passenger boarding bridge. They are available in both ground-mounted and bridge-mounted configurations and are prepared to be connected to a centralized management system.

Quality is a must. All components are designed, manufactured and tested in order to offer a service life of at least 15 years. Maintenance tasks can be carried out fast and easy on any component inside the unit thanks to ADELTE’s direct access design. Remote maintenance and monitoring are available to enhance PCA operations.

Zephir PCA is designed according the latest technologies. The PLC can be accessed remotely o via its user-friendly touch screen interface allowing operators to control all parameters of the PCA during operations, monitoring or maintenance phases.

Conceived to provide passengers with an outstanding experience, Zephir PCA uses G4 filters (F5 to F9 filters optional) to supply high quality air inside the aircraft and reinforced thermo acoustic insulation for significant noise reduction.

Axial EC FAN

The latest generation axial fans EC reduce the electrical consumption thanks to a stepless/continuous regulation.

- Mode of operation: Continuous operation (S1)

- Control input 0-10 VDC / PWM

- Type of protection: IP 54 (acc. to EN 60529)

- Insulation class: "B" ("F" applying to the main components as per EN)

- Bearings: Maintenance-free ball bearings

High durablity materials

ADELTE’s PCA is designed to work under all environments around the world. The high quality of the structure and the panels assures lifespan to the equipment in exteriors, stand or bridge mounted.

- Heat exchanger grill protector

- Side metal panels with great thermal insulation.

- Noise insulation for a better boarding experience

- Quality coating of the steel structures and endurance for the life of the structure (20+ years)

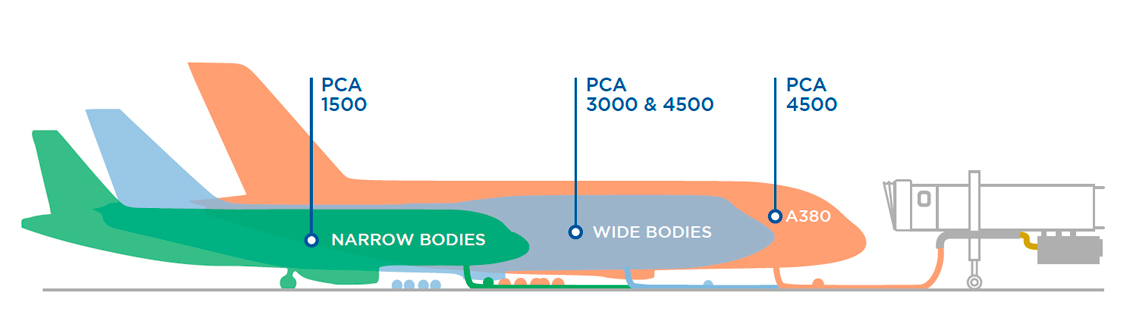

Narrow Bodies

Wide Bodies

WIDE BODIES & A380